Open Mike on Shield Control Cable

본문

It is going to be used between items of equipment intentionally tied to the same floor (we call out within the specification that this must be the case). Many of these similar technicians and radiological officers are also atop the decision lists in their respective states for any radiological emergency and many of these identical radiation detector survey meters and dosimeters are what they are going to be confidently responding with. Survey meters, field survey meters, charge meters, radiac meters, radiation detection meters, low-range meters, excessive-vary meters, airborne meters, fallout meters, distant screens, Geiger counters, and even 'dose rate meters' are all describing devices, tools and units that detect and measure publicity price or the depth of radiation at a location at some point in time. More information on the precise bodily harm caused by gamma radiation is under within the section entitled: Which Survey Meter Can be Best For My Needs? Electrical leakage in dosimeters creates motion or drift of the fiber from an preliminary setting OR in direction of an up-scale studying with out the presence of radiation. However, those who do go the electrical leakage test and in addition the radiation publicity accuracy check, needs to be held in high confidence of performing accurately and reliably in the sphere.

It is going to be used between items of equipment intentionally tied to the same floor (we call out within the specification that this must be the case). Many of these similar technicians and radiological officers are also atop the decision lists in their respective states for any radiological emergency and many of these identical radiation detector survey meters and dosimeters are what they are going to be confidently responding with. Survey meters, field survey meters, charge meters, radiac meters, radiation detection meters, low-range meters, excessive-vary meters, airborne meters, fallout meters, distant screens, Geiger counters, and even 'dose rate meters' are all describing devices, tools and units that detect and measure publicity price or the depth of radiation at a location at some point in time. More information on the precise bodily harm caused by gamma radiation is under within the section entitled: Which Survey Meter Can be Best For My Needs? Electrical leakage in dosimeters creates motion or drift of the fiber from an preliminary setting OR in direction of an up-scale studying with out the presence of radiation. However, those who do go the electrical leakage test and in addition the radiation publicity accuracy check, needs to be held in high confidence of performing accurately and reliably in the sphere.

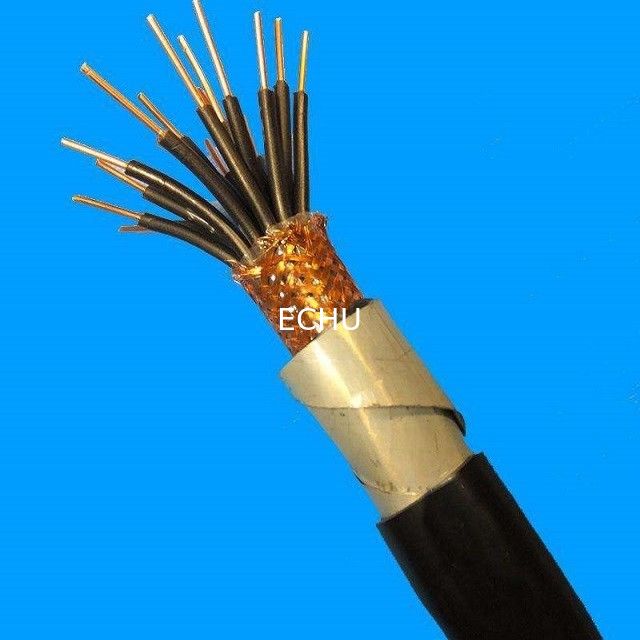

Cables pass IEEE1202/CSA FT4 (70,000 BTU/hr) cable tray flame check. Cables meet necessities of ICEA S-73-532, NEMA WC57 for Control Cables. The outer jacket is very versatile abrasion-resistant grey polyvinyl chloride thermoplastic, assembly the requirements of U.L. In the protective layer 6, shield control cable numerous supplies conventionally known similar to polypropylene and polyvinyl chloride can be utilized. They know first-hand how effectively they hold up their calibration and may be counted on to perform. Civil Defense meters and dosimeters we'd acquired from the Federal Depot in 2001, together with numerous tons of more from state and municipal agencies and individuals who've despatched theirs into us for calibration. Here at KI4U we offer only calibrated Civil Defense meters. For example, a technique comprising ading the organopolysiloxane having an ultra-high viscosity and the organopolysiloxane having a lower viscosity separately to the thermoplastic resin while heating and kneading the thermoplastic resin and uniformly dispersing them, a way comprising including the organopolysiloxane, which is beforehand prepared by mixing the organopolysiloxane having an extremely-excessive viscosity and the organopolysiloxane having a lower viscosity in a prescribed proportion, to the melted thermoplastic resin and uniformly dispersing them, and the like could be exemplified.

It is preferable that the elastomer has an capability to be modified in order that a softened polyphenylene sulfide, which is prepared by mixing with the elastomer and kneading them with melting, has a flexural modulus of at most 30000 (ASTM D 790) and a tensile elongation at break of at the very least 5% (ASTM D 638). Representative examples of such an elastomer are, as an example, an olefin copolymer containing an epoxy group (ethylene content material: 88% by weight, glycidyl methacrylate content: 12% y weight), a hydrogenated styrenebutadience copolymer (TUFTEC M 1913 commercially accessible from Asahi Chemical Industry Co., Ltd.), an ethylene-propylene copolymer (TAFMER PO 680 commercially available from MITSUI PETRO CHEMICAL INDUSTRIES, LTD.), and the like. When the paste-extrusion method is employed, it is preferable that paste is prepared by including kerosene to polytetrafluoroethylene powder and kneading them, the paste is extruded to provide a tube under high stress and a stranded steel wire is coated with the tube, and after that, the stranded steel wire is dried and baked in a furnace reminiscent of an electric furnace.

When the melt index of the high density polyethylene is lower than 0.01 g/10 minutes, the extrusion molding becomes tough, and there's a tendency that the inside coat can't be fastened on a stranded steel wire. Accordingly, it's preferable that the melt index is 0.5 to 5 g/10 minutes. When the melt index of the polyoxymethylene is lower than 0.5 g/10 minutes, moldability deteriorates as a result of there's a necessity to heat the polyoxymethylene to nearby a temperature of the thermal decomposition. When the melt index is greater than 5 g/10 minutes, there's a tendency that bending energy, influence resistance and abrasion resistance deteriorate. When the melt index is more than 5 g/10 minutes, there's a tendency that oil resistance, stress cracking resistance and abrasion resistance deteriorate. Accordingly, it's preferable that the melt index is 0.01 to 5 g/10 minutes. Also, when the melt index is too large, the polybutylene terephthalate lacks toughness and cracks are generated within the internal coat, and the liner is usually broken when the internal coat is rapidly bent in the assembling process of a management cable.

댓글목록0

댓글 포인트 안내